Article on bulk-online

Dear Business Friends,

We would like to inform you that one of the most visited specialised portals bulk-online has published an article about us.

Yours,

kešner a.s.

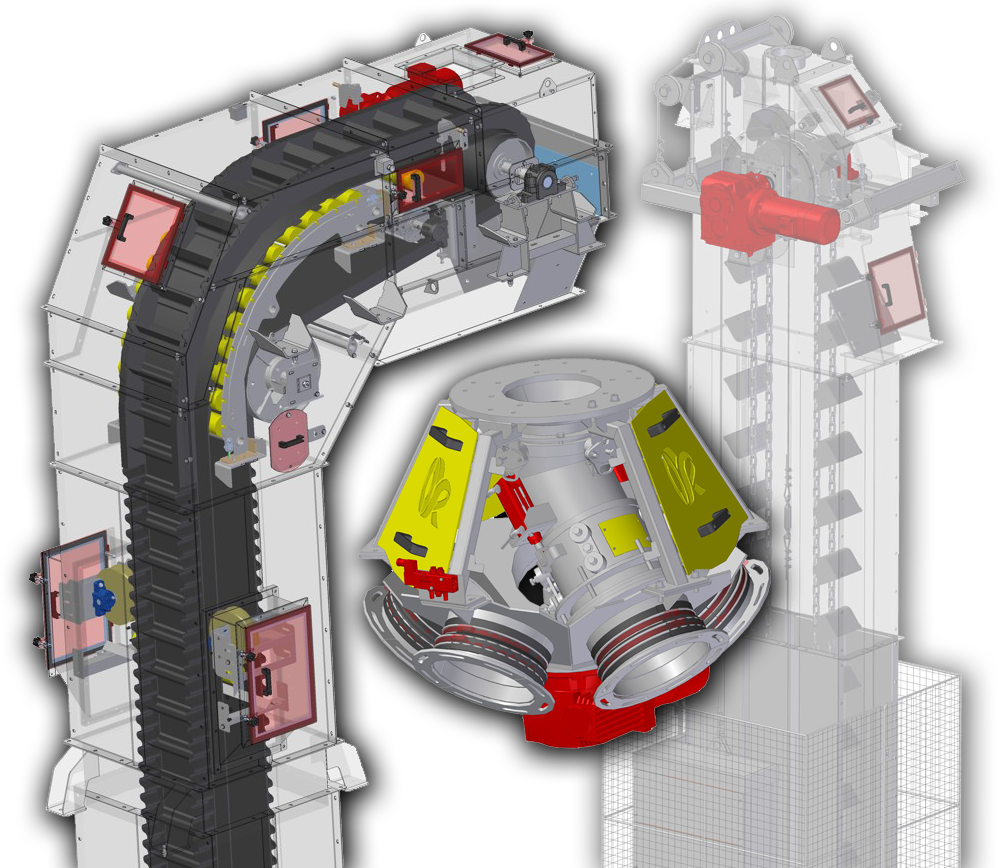

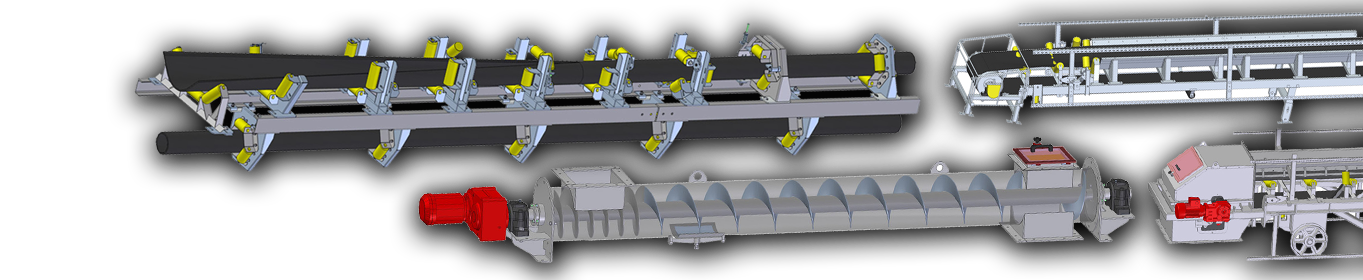

Rotary feeder (TPD)

Use:

Rotary feeder is intended for conveying and controlling flow of loose non-sticky materials. It can also fulfill the function of shutting-off. It is possible to adjust the rate/throughput of conveyed material by setting the feeder rotor speed with the help of frequency inverter. Rotary feeders are offered from material as ordinary steel, then also as a combination with wear resistant steel or with stainless steel. Rotary feeder is fabricated also in non-standard dimensions, which is adapted to erection and connecting dimensions.

Dimensions and parameters:

| Feeder diameter (mm) |

Basic feeder dimensions [fl ange AxB/H-height (mm)] |

Conveying rate * (m3/h) |

|

| 219 | 200 x 200 / 290 | 9 | |

| 245 | 250 x 250 / 420 | 17 | |

| 324 | 320 x 320 / 500 | 29 | |

| 406 | 400 x 400 / 600 | 58 | |

| 508 | 500 x 500 / 750 | 118 | |

| 630 | 630 x 630 / 880 | 210 | |

* final conveying rate depends on properties of each material and possible % filling ratio

Remark:

- Dimension of rotary diverting gate and parameters of volume throughput incl. grain size are subject to technical analysis and calculation.

Inquiry

* If the customer cannot deliver a reply to the mentioned enquiries, price offer will be processed on the basis of estimations and experience from previous projects.

Remark: Inquiry does not contain any requested data on signaling and safety elements by reason that we do not offer the delivery of electrical and control equipment for the conveyor. As offer/delivery is put into effect, we fully provide technical support and coordination with the supplier, incl. delivery of fastening accessories on conveyor.